Hardware and software

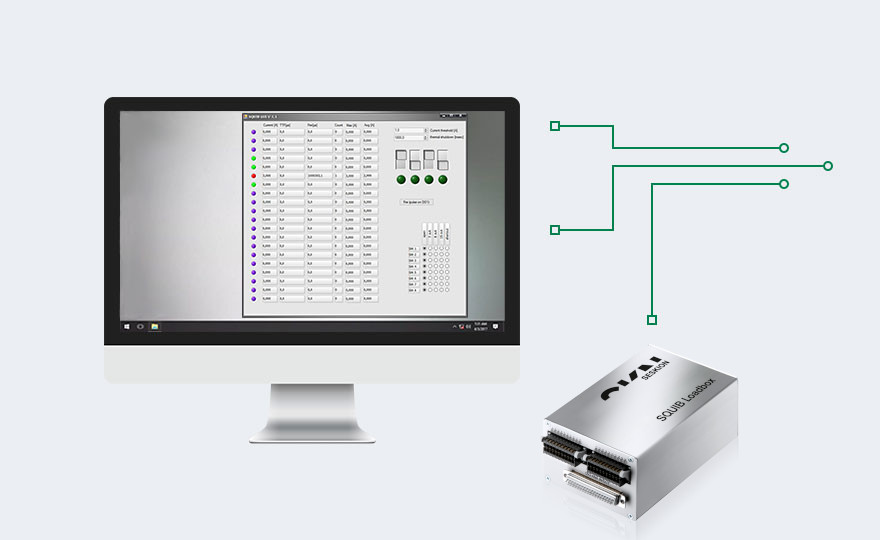

SQUIB Box

The SQUIB box is used to check the triggering mechanisms of airbag control units. The SQUIB box allows the recording of voltages and currents during the release.

Professional data simulation

Facts about the SQUIB Box

In addition to the standard version, Seskion also offers modified versions as well as advanced hardware and software solutions for special measurement requirements.

- Standard Windows Gui Anwendung (optional)

- API-ANSI-C (included in the box)

- LabVIEW Lib (optional)

- Windows GUI application for SQUIB-Box will be installed with the Installer of PSI5-Simulyzer and is located in “C:\Program Files (x86)\SesKion GmbH\PSI5-Simulyzer\SQUIB_GUI.exe”

| Interfaces | USB 2.0 and connections for control unit and sensor |

| Power supply | via USB or external plug Power supply unit |

| Compatible systems | Windows-7 +10, Microsoft .NET Framework 2.0, Linux (only API, no GUI) |

| Recording options | Recording of voltages and currents at 100 kS/s |

| Data export | via API |

Simulyzer-Box

5.1001 SQUIB-Box for simulation of switches to be monitored and voltage measurement of SQUIB-drivers. Simulation of 8 switches and 20 SQUIB-stages, with DLL and GUI.

Additional

9.0001 Optional warranty extension of the Simulyzer Box to 3 years

9.0011 LabView-2016 Library, 32- or 64-bit. PC-ID or Box-SN bound license

9.0012 LabView-2016 Library, 32- or 64-bit. Company license

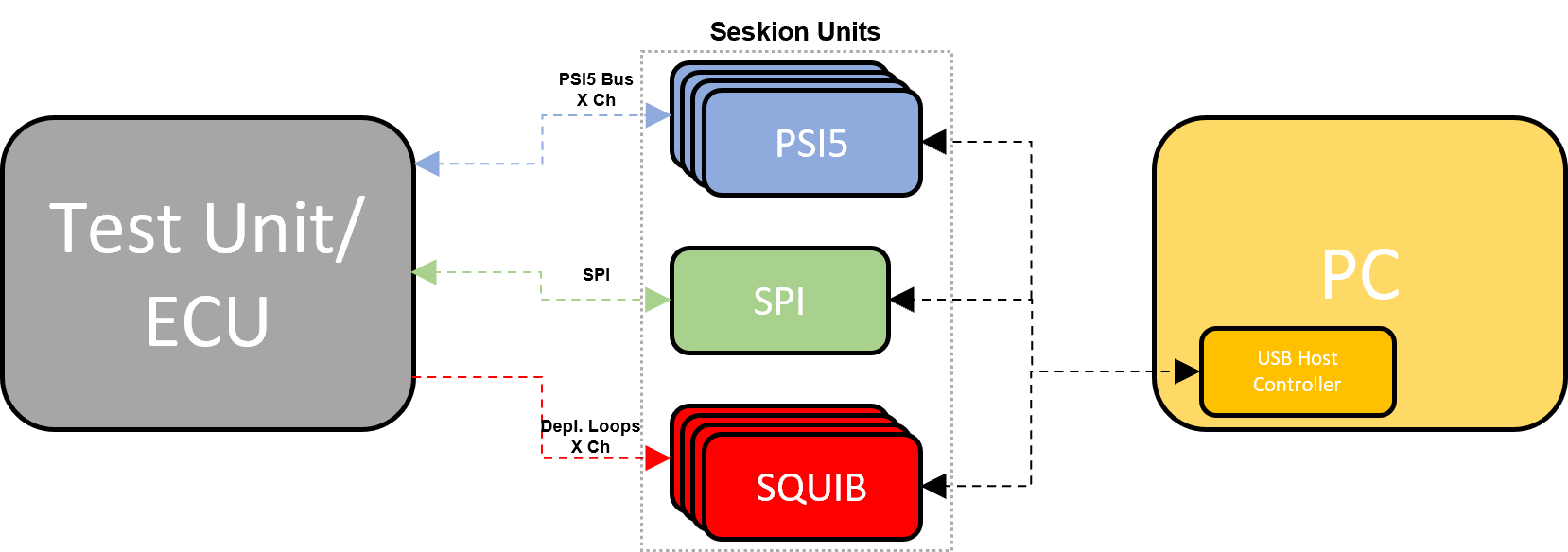

HiL-Simulation for Airbag ECU

To generate a complete HIL simulation for an airbag control unit, the internal acceleration sensor signals of the control unit (SPI) and the peripheral acceleration and pressure sensor signals (PSI5) must be connected. Also the ignition timing can be measured and analyzed by using the SQUIB box. Furthermore, a PC system connected to the simulators via a USB port/network is used for data processing.

Often up to 6 or more PSI5-Simulyzer are operated together with several SPI-Simulyzer. For coordination there is a superordinate configuration, which determines which Simulyzer is used, which signal traces are used by which Simulyzer and which detailed configurations are to be used with the bus parameters. By using the superordinate configuration, the operation of the API is very simple. A continuous control of the sensor signals can also be made.