Routine testing at the end of the production line

Production logging and final configuration

A possible application for the Simulyzer Boxes and the Simulyzer RT is the control and logging of the produced sensors in different manufacturing stages. Here internal data such as serial numbers as well as plausibility of measured values can be tested. As an extension it is also possible to program non-volatile parameters in the sensors.

Production logging and final configuration in practice

Our Simulyzer products are used in the following manufacture stages:

- Sensor chip production

- Housing integration of sensors

- Integration of complete sensors in cable harnesses

- Complete automotive parts (e.g. bumper)

Integration of complete sensors in wire harnesses and complete automotive parts is inserted. Digital inputs and outputs can be used as interfaces to programmable logic controllers (PLCs) or network interfaces such as Modbus-TCP.

The PLC gives the Simulyzer a start-signal and receives the message OK-Finished or FAIL-Finished within fractions of a second.

To program PSI5 sensors, the addresses to be programmed with their values can be specified in a script file.

An example of use

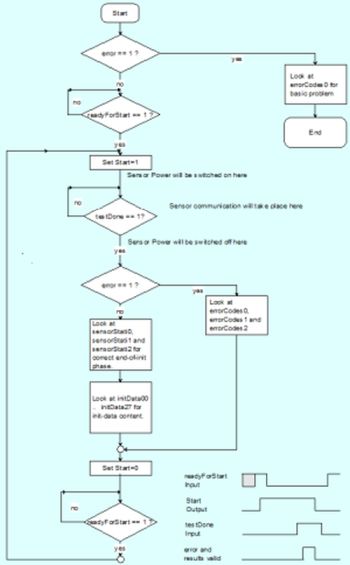

A typical sequence in a PLC contains the following steps, shown in the figure.

SesKion offers an API library for this type of application on the one hand and various Windows and Linux applications on the other.

Possible types of sensor interfaces:

- SPI

- PSI5

- SENT

- DSI.

The API is available as ANSI-C(++) as well as .NET API (C# …) and LabVIEW. Adaptations to Matlab and Phyton are possible.